June news from MEPAC SK s.r.o.

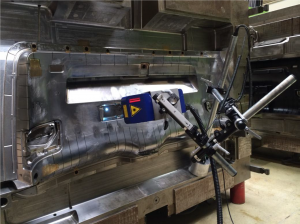

Did you know why the size doesn’t matter by using HCP 20?

Doesn`t matter of crisis the mobility, and the goal of providing the best services associated with saving customer costs is important for us. That’s why we’ve expanded our technology park with the new HCP 20 mobile laser engraving system. The HCP 20 is a unique system from the MEPAC group. It`s designed for engraving molds, tools also with a complicated shape, regardless of their size and weight. It also can replace micro-milling or EDM machining. By engraving with a laser beam on plastics, it`s also possible to obtain color effects at the point of impact of the laser beam according to the type of plastic and replace the tampon-printing. Of course, our system meets the strictest criteria and requirements for mobile, fast, and precise engraving. We can provide all mobile engraving services directly for you on-site with the best quality and express speed.

Thanks to our machine park, which also includes WEDM we`re precise.

WEDM (Wire Electrical Discharge Machining) has many advantages such as low cost, essentially no waste, but also extreme precision, which allows you to cut also very small accurate diameters. Such diameters are used, for example, in the production of microparts, injector pins or medical needles, etc.. Of course, EDM is not only intended for the production of microparts, but we also use it for the production of larger pieces up to the dimensions of 1,050 x 800 x 300 mm and up to a maximum weight of 1,500 kg. Hmmm and what exactly EDM is? It`s electro-erosive machining, ie the process of removing the workpiece material, which occurs electrically and especially with non-contact and with zero force. The whole process runs with the help of rapidly repeating periodic pulses of spark discharge in the presence of a liquid medium. Thanks to EDM wire cutting, we have already helped many of our customers and delivered products exactly according to their wishes.

Did you know which CMM is the most precise and best?

There are many different CMMs (coordinate measuring machines) on the market, but this miracle represents the fully automated CMM from the MIRACLE series. It is a newly developed system from Leader Company that takes all benefits from CMM systems from around the world. Its equipment can include touch and non-touch sensors, or a precise laser scanning system up to the very precise OCD optical design of fast scanning. The overall design of the CMM is one of the highest quality components, whether if we talking about quality servo motors, granite workbench, but also probe equipment from Renishaw. MIRACLE is available in many versions of the permissible load, also even parts weighing 1,800 kg, for example, are not a problem to measure. The entire MIRACLE system works with RATIONAL-DMIS software, which is awarded by the PBT certificate and is also as an I ++ software.